The role of the car clutch

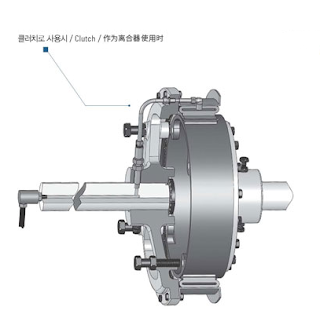

Whether it is a heavy truck, a bus or a car, it is inseparable from the clutch platen and the clutch plate to form a car clutch. What role does the car clutch play in the operation of the car?

The role of the clutch is summarized as follows:

1. Ensure that the car starts smoothly

2. Easy to shift gears

3. Prevent transmission system overload

4. Reduce the torsional vibration shock

1. Ensure that the car starts smoothly: Before the start, the car is at a standstill. If the engine( Howo parts, Sinotruk spare parts )and the gearbox are rigidly connected, once the gear is engaged, the car will suddenly thrust forward due to the sudden connection of the power, which will not only cause damage to the machine, but also drive. The force is not enough to overcome the huge inertial force generated by the car's forward thrust, causing the engine speed to drop sharply and turn off. If the clutch is temporarily used to separate the engine from the transmission at the start, and then the clutch is gradually engaged, the torque transmitted from the clutch can be gradually increased from zero due to the slipping phenomenon between the active portion and the driven portion of the clutch. The driving force of the car is also gradually increased, so that the car starts smoothly.

2. Easy to shift: During the driving process, different gearbox positions are often used to adapt to changing driving conditions. If there is no clutch to temporarily separate the engine from the transmission, the meshing gears( Howo parts, Sinotruk spare parts )that are engaged in the transmission are not removed due to the load, and the pressure between the meshing surfaces is large and difficult to separate. The other gear to be meshed is difficult to engage due to the unequal circumferential speed of the two. Even if it is forced into the mesh, it will cause a large tooth end impact and easily damage the machine. When the engine and the transmission are temporarily separated by the clutch and then shifted, the original pair of gears are removed by the load, and the pressure between the meshing surfaces is greatly reduced, so that it is easy to separate. The other pair of gears to be engaged, because the driving gear is separated from the engine, the moment of inertia is small, and the appropriate shifting action can make the circumferential speeds of the gears to be meshed equal or nearly equal, thereby avoiding or reducing the impact between the gears.

3. Prevent the drive train from being overloaded: When the vehicle is in emergency braking, the wheel suddenly drops sharply, and the drive train connected to the engine maintains the original speed due to the inertia of rotation, which tends to generate much more than the engine torque in the transmission system. The moment of inertia makes the parts of the drive train susceptible to damage. Since the clutch transmits torque by friction, when the load in the drive train exceeds the torque that can be transmitted by the friction force, the main and driven parts of the clutch will automatically slip, thus preventing the drive line from being overloaded. .

4. Reduce the torsional vibration: The working principle of the car engine determines the instability of its output torque. In the power stroke, the combustion chamber gas explosion produces a very large impact torque, while in other strokes, the engine( Howo parts, Sinotruk spare parts )is reversed by inertia. Although the inertia of the engine's own rotating system can reduce the torsional vibration, the remaining impact force still adversely affects the subsequent gearbox and transmission shaft. The damping spring (tangential distribution) in the clutch can significantly reduce the torsional vibration caused by the engine and prolong the life of the shifting gear.

The role of the clutch is summarized as follows:

1. Ensure that the car starts smoothly

2. Easy to shift gears

3. Prevent transmission system overload

4. Reduce the torsional vibration shock

1. Ensure that the car starts smoothly: Before the start, the car is at a standstill. If the engine( Howo parts, Sinotruk spare parts )and the gearbox are rigidly connected, once the gear is engaged, the car will suddenly thrust forward due to the sudden connection of the power, which will not only cause damage to the machine, but also drive. The force is not enough to overcome the huge inertial force generated by the car's forward thrust, causing the engine speed to drop sharply and turn off. If the clutch is temporarily used to separate the engine from the transmission at the start, and then the clutch is gradually engaged, the torque transmitted from the clutch can be gradually increased from zero due to the slipping phenomenon between the active portion and the driven portion of the clutch. The driving force of the car is also gradually increased, so that the car starts smoothly.

2. Easy to shift: During the driving process, different gearbox positions are often used to adapt to changing driving conditions. If there is no clutch to temporarily separate the engine from the transmission, the meshing gears( Howo parts, Sinotruk spare parts )that are engaged in the transmission are not removed due to the load, and the pressure between the meshing surfaces is large and difficult to separate. The other gear to be meshed is difficult to engage due to the unequal circumferential speed of the two. Even if it is forced into the mesh, it will cause a large tooth end impact and easily damage the machine. When the engine and the transmission are temporarily separated by the clutch and then shifted, the original pair of gears are removed by the load, and the pressure between the meshing surfaces is greatly reduced, so that it is easy to separate. The other pair of gears to be engaged, because the driving gear is separated from the engine, the moment of inertia is small, and the appropriate shifting action can make the circumferential speeds of the gears to be meshed equal or nearly equal, thereby avoiding or reducing the impact between the gears.

3. Prevent the drive train from being overloaded: When the vehicle is in emergency braking, the wheel suddenly drops sharply, and the drive train connected to the engine maintains the original speed due to the inertia of rotation, which tends to generate much more than the engine torque in the transmission system. The moment of inertia makes the parts of the drive train susceptible to damage. Since the clutch transmits torque by friction, when the load in the drive train exceeds the torque that can be transmitted by the friction force, the main and driven parts of the clutch will automatically slip, thus preventing the drive line from being overloaded. .

4. Reduce the torsional vibration: The working principle of the car engine determines the instability of its output torque. In the power stroke, the combustion chamber gas explosion produces a very large impact torque, while in other strokes, the engine( Howo parts, Sinotruk spare parts )is reversed by inertia. Although the inertia of the engine's own rotating system can reduce the torsional vibration, the remaining impact force still adversely affects the subsequent gearbox and transmission shaft. The damping spring (tangential distribution) in the clutch can significantly reduce the torsional vibration caused by the engine and prolong the life of the shifting gear.

Comments

Post a Comment